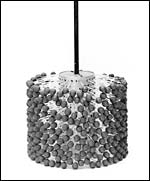

the Flexible

Cylinder Hone Tool

For

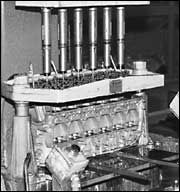

Any Type and Size of Cylinder...

For

Any Type and Size of Cylinder...

Cylinder Honing a metallic product (Super Finishing) produces a controlled

surface condition unobtainable by any other method. It involves finish,

geometry and metallurgical structure. A high percentage plateau free of

cut, torn and folded metal (with radiused ports).

A resilient, flexible, honing tool with a soft cutting action. The abrasive (points) globules each have independent suspension that assures the Flexible Cylinder Hone to be self-centering, self aligning to the bore and self-compensating for wear.

Specifically, it is a low-temperature abrading process that exposes the undisturbed base metal structure to produce a long wearing surface. It is a method of developing a surface on a metal part which is optically smooth and metallurgically free of any fragmented, amorphous or smeared metal from previous operations. It is accomplished at a low pressure where the “stones” float across the surface. The final achieved finish ensures a superior performance in situations dependant on the condition of the surface.

The unique crosshatch created by a Flexible Cylinder Hone is extremely efficient.

It provides a multiplicity of oil grooves or valleys for oil retention,

as opposed to the often un-directional or uneven valleys common to the

conventional type rigid hone. These crosshatch patterns remains longer

than the rigid ones, as the

cylinder wall is wear-reduced after hours of use.

.jpg)

.jpg)